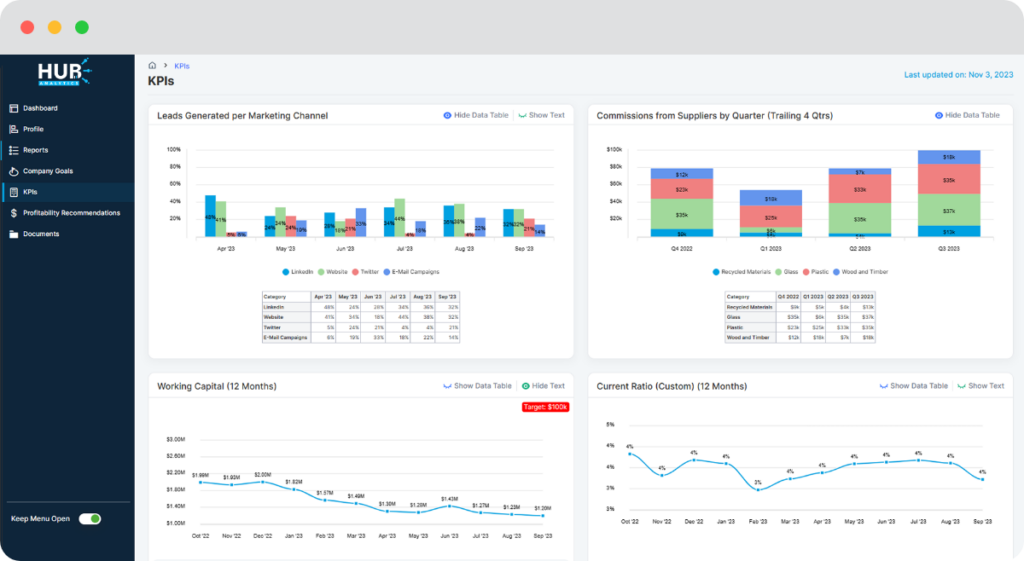

Explore crucial metrics and KPIs to optimize operations and boost profitability.

Metrics, or Key Performance Indicators (KPIs), are measurable values offering insights into manufacturing performance. By tracking these indicators, informed decisions can guide your company toward success.

In manufacturing, tracking key metrics is essential for effective management. These metrics range from production efficiency to supply chain performance, ensuring businesses stay competitive and profitable.

Monitor the ratio of actual production output to the standard output, ensuring optimal manufacturing efficiency.

Production Efficiency = (Actual Output / Standard Output) 100

Gauge how quickly inventory is sold and replaced, optimizing cash flow and preventing overstock.

Inventory Turnover = Cost of Goods Sold / Average Inventory

Assess the proportion of high-quality products manufactured, minimizing defects and rework costs.

Quality Yield = (Number of Good Units / Total Units Produced) x 100

Measure the time it takes to fulfill a customer order, enhancing customer satisfaction and on-time deliveries.

Lead Time = Total Manufacturing Time / Number of Units Produced

Track the percentage of time equipment is idle, identifying areas for improvement in production uptime.

Downtime Percentage = (Downtime / Total Time) x 100

Evaluate the percentage of unusable materials or products, reducing waste and improving resource efficiency.

Scrap Rate = (Weight of Scrap / Total Weight of Materials Used) x 100

Assess the effectiveness of equipment usage to optimize production capacity and resource allocation.

Equipment Utilization = (Actual Equipment Operating Time / Total Available Time) x 100

Track the percentage of orders delivered on time, enhancing customer satisfaction and

maintaining reliable supply chain relationships.

On-Time Delivery = (Number of On-Time Deliveries / Total Deliveries) x 100

Evaluate supplier reliability and quality to ensure a stable and efficient supply chain.

Supplier Performance = (Number of Defective Deliveries / Total Deliveries) x 100

Analyze the proportion of revenue spent on raw materials, optimizing cost efficiency.

Material Costs Percentage = (Material Costs / Total Revenue) x 100

Monitor the value of products in the production process, optimizing workflow and resource allocation.

WIP Inventory = Cost of WIP Inventory / Number of Units in Progress

Assess the efficiency of labor resources in production, optimizing workforce management.

Employee Productivity = Total Output / Number of Employees

Evaluate the energy efficiency of manufacturing processes, reducing environmental impact and costs.

Energy Consumption per Unit = Total Energy Consumption / Total Units Produced

Monitor adherence to regulatory standards and certifications, ensuring legal and industry compliance.

Compliance Rate = (Number of Compliant Products / Total Products Produced) x 100

Measure the efficiency of asset utilization in generating profits, optimizing resource allocation.

ROA = Net Income / Average Total Assets

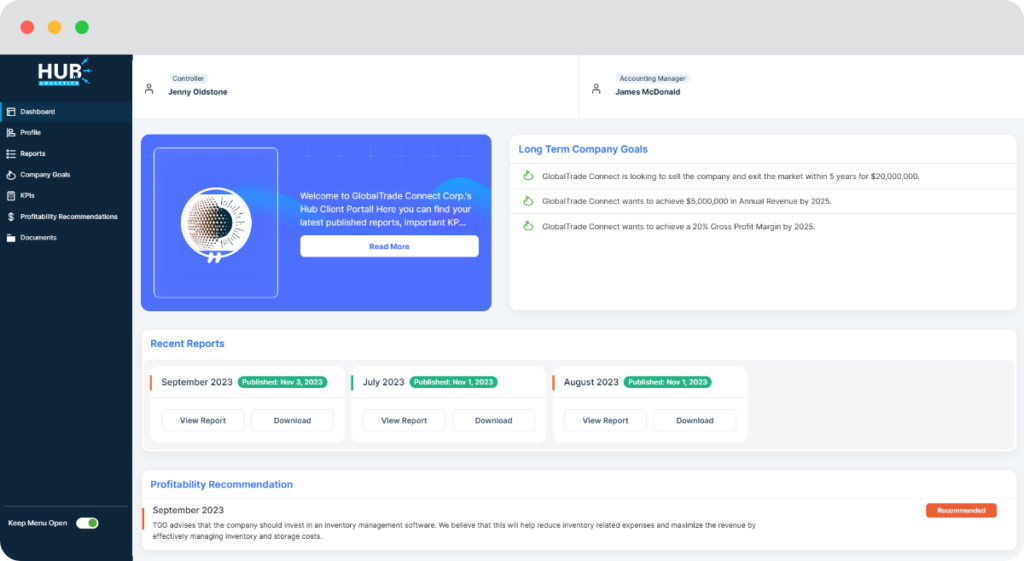

Every manufacturing business is unique. Explore the process of selecting metrics aligned with your goals. Whether you’re a manager, consultant, or investor, gain actionable insights to refine your financial strategy.

Ready to enhance your manufacturing financial strategy? Start tracking essential metrics with HUB today. Optimize performance, gain valuable insights, and make informed decisions for lasting success. Your financial journey begins here.